CONTAINMENT VALVE MCV

Robust and stable split butterfly valve system for handling of solids, to transfer and fill highly active or toxic media

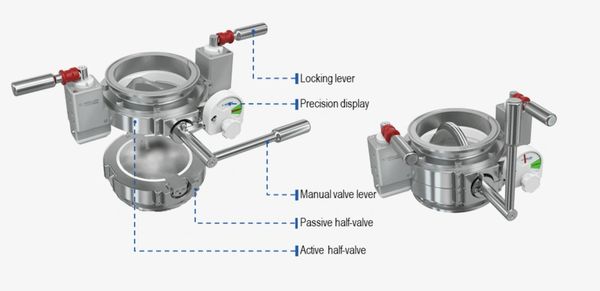

The split butterfly valve system is made of an active and a passive section. The active section includes the mechanism for locking the active and passive sections, as well as a hand lever or an actuator for opening and closing the valve disks.

The active section is for example attached to the machine inlet / outlet, the passive section to the transport container. To open the valve system, both valve halves are coupled to each other Sturdy and GMP-compliant locks ensure precise positioning.

Once the two valve halves are locked, a closed system is established and the valve can be opened manually or automatically.

The split butterfly valve system is designed according to GMP aspects, it is quick and easy to clean and it meets the current requirements for compliance with occupational exposure limit values.

feattures

Type

- Nominal diameter DN 65, 100, 150, 200 u. 250

- ATEX variant up to zone 20 in the product-contacted area

- Version with up to +6 bar operating pressure according to Pressure Equipment Directive 2014/68/EU Module A1

Manual stroke variant

Due to the manual operation no separate safety devices, pneumatic connections or controls are necessary. Neither the container nor the machine has to perform a lifting movement.

The suspension on robust wire ropes allows performing a lifting stroke of 65mm. With a pre-positioned container, the manual lifting device allows for a large tolerance compensation.

Pneumatic variant

The pneumatic stroke and the pneumatic valve actuation ensure fully automatic coupling operations. Once the container is positioned, neither the container nor the machine are to perform any lifting movement.

To ensure soft docking without stroke of the active valve, the stroke can be performed by a spring-pneumatic suspension. In this variant, the container with the passive valve is gently placed on the spring damper of the active valve.

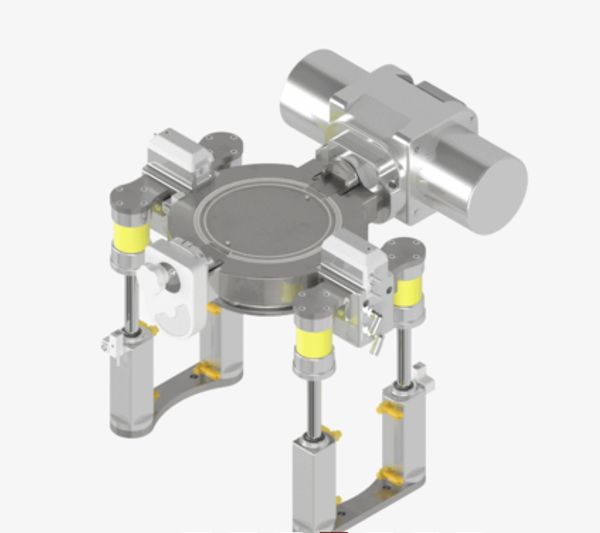

Mounting frame variant

For particularly fast product change. Connections, sensors and actuators remain connected to the machine with the mounting frame. The product-contacted active valve can be replaced in shortest time thanks to a quick release.

Material

- product-contacted components made of PTFE and 1.4404 / 316L or Hastelloy C22

- seals for a wide range of applications, optionally in EPDM or Kalrez, with FDA approval

Benefits

- for powdery products, OEL < 1 µg / m³. Tested according to ISPE SMEPAC guideline

- protects against cross-contamination

- optimal operator safety

- optimized product protection

- entirely closed product handling

- supports the compliance with the regulatory requirements of the chemical and pharmaceutical industry

- explosion pressure shock resistant and flame-arresting up to 10 bar

- no product trapped in the sealing area

Specials

- quality management according to ISO 9001:2015

- product-contacted materials with inspection certificates according to DIN EN 10204 / 3.1, where necessary 3.2

- certified according to the Pressure Equipment Directive (PED) 2014/68/EU Module A1. Manufacturer approved in compliance with the AD 2000 leaflet HP 0 and TRD 201 in connection with DIN EN ISO 3834-2

- seals certified according to FDA CFR 21 §177.2600 and. §177.1550

- ATEX-compliant design possible in all variants, approved according to 2014/34/EU

- explosion pressure shock resistance and flame-arresting tested up to 10 bar

Usage

Can be used for

- Filling

- Weighing

- Equipment feeding

- Mixing

- Drying (inlet or outlet)

- Dry and wet granulation

- Filtration

- Sieving and grinding

- Coating

- Sampling

Attachments

On request

- Cleaning solutions

- Ready-to-use control solutions

- Leakage test equipment

Handling

Step 1

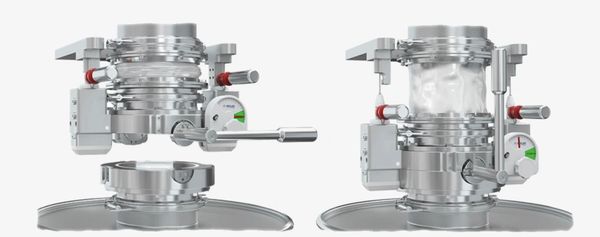

Each of the active and passive valve half forms a closed unit. The valve disk is secured against inadvertent opening.

Step 2

When coupled, the two valve disk halves form one common valve disk.

The passive section of the valve disk is driven by the actuating elements of the active section.

Step 3

The coupled half disks are turned around their common axis to the open position. The product can start flowing.

The areas located outside before coupling are still isolated from the product-contacted area.

After closing and uncoupling the valve halves, the outer areas of the valve disks and of the split butterfly valve did not have any contact with the product-contacted inner areas.

Vinisa E. I. Pvt. Ltd.

G-28, T.V. Industrial Estate, S.K. Ahire Marg, Worli, Mumbai, Maharashtra, INDIA.

Office: +91 22 2490 0317 Email: info@vinisa.in